When it comes to improving energy efficiency and lowering investment requirements in the process industries, modular chemical process intensification (MCPI) has been a long-standing concept. In general, though, MCPI deployment in energy-intensive industries has been limited by several barriers, including:

- Capital costs and RAM (reliability/availability/maintenance) risk involved in committing to new processes

- High complexity of an intensified, modular system, without simplifying standardization techniques

- Insuffcient software and design tools and data to develop intensified processes

- Challenge (technical, economic, and re: intellectual property) of developing standardized design and manufacturing protocols for a complex new technology space at an early point in its technical and commercial development

- Limited understanding of design and operation of MCPI technologies across a broad range of key industry participants

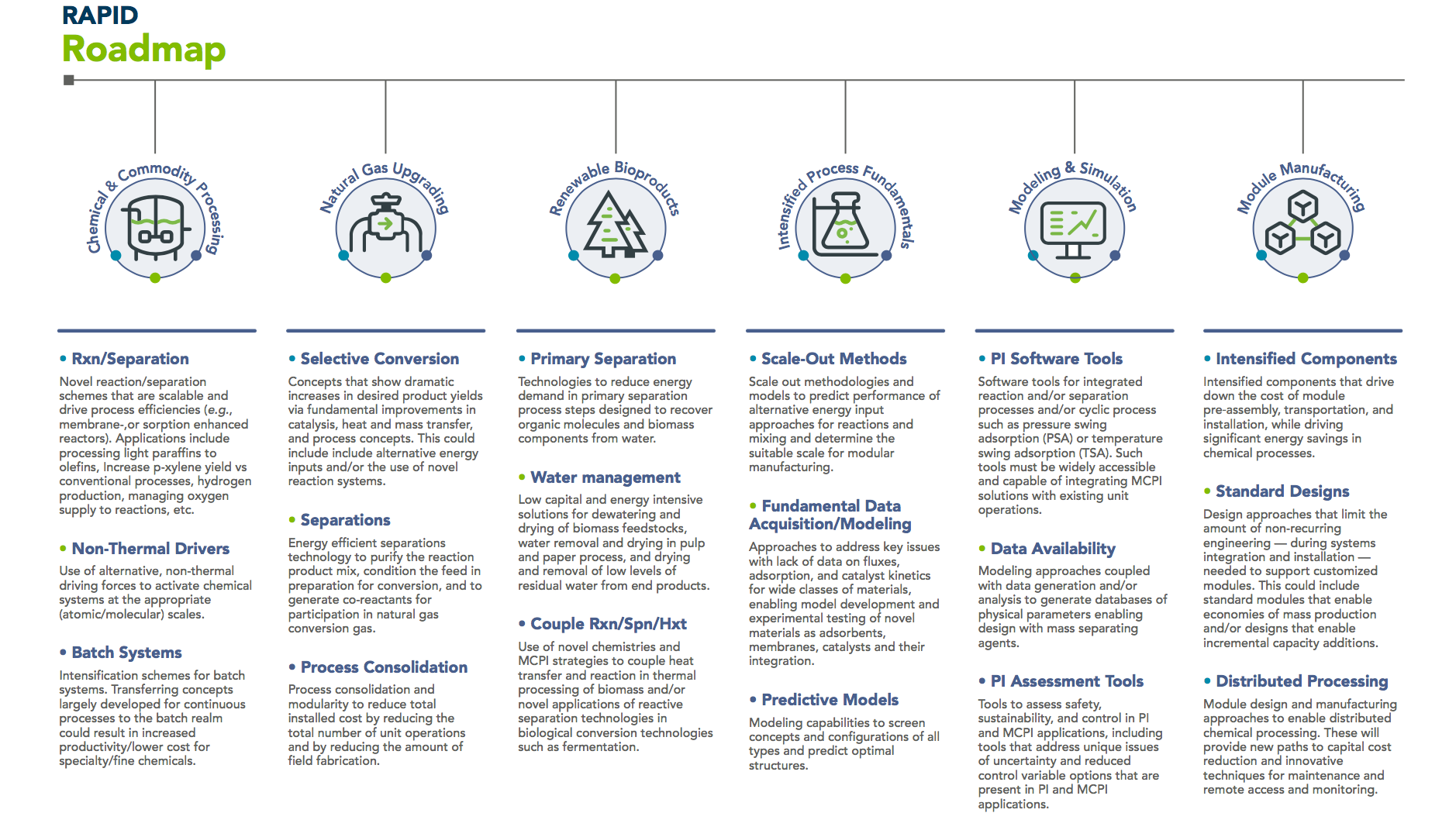

In December, 2016, the Department of Energy announced the establishment of the 10th Manufacturing USA Institute, representing a critical step in the federal government’s effort to double U.S. energy productivity by 2030. The Rapid Advancement in Process Intensification Deployment (RAPID) Institute is focused on addressing the barriers listed above to enable the development of breakthrough technologies to boost energy productivity and energy efficiency through manufacturing processes in industries such oil and gas, pulp and paper and various domestic chemical manufacturers. RAPID will leverage approaches to modular chemical process intensification (MCPI) — such as combining multiple process steps such as mixing, reaction, and separation into single more complex and intensified processes — with the goal of improving productivity and efficiency, cutting operating costs, and reducing waste.